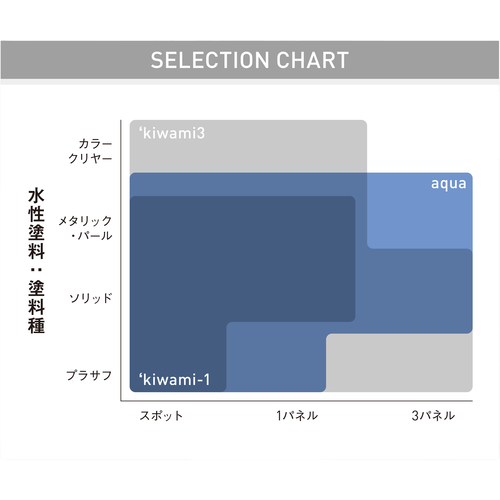

Inheriting the features of WIDER1 and making it easier to use and design than ever before.

We believe that the most important thing when it comes to automotive repair spray guns is to be able to quickly adapt to evolving paints, maximize the performance of the paints, and easily and beautifully paint. A spray gun must be the ``ultimate tool'' for our customers. 14 years have passed since the release of the 2-component paint spray gun "Bisho" series, and 10 years have passed since the release of the 1-component high solid paint spray gun "Kiwami" series. Nowadays, environmental considerations, worker safety, simplifying painting work, and improving quality are required. We aim to further raise the level of "extreme" and become the "ultimate tool" for our customers.

Features of KIWAMI-1-13B10

A spray gun that can handle highly difficult painting. The film thickness and particles within the pattern are uniform, making it suitable for color clears, gun metallics, pearl bases, etc. that have been increasing in recent years, and achieving an optimal wet coating.

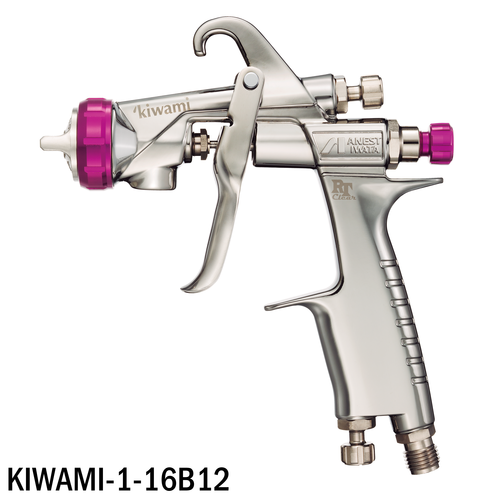

Features of KIWAMI-1-16B12

A spray gun compatible with non-diluted high solid clear. Adopting a nozzle diameter of 1.6mm, it achieves a large discharge amount and highly atomized particles. The wide pattern and high atomization performance allow you to freely control the coating surface, dramatically increasing work efficiency.

Features of KIWAMI-1-18B14

The Φ1.8mm large-diameter nozzle improves the amount of paint ejected by 60% (compared to KIWAMI-1-13B8) while maintaining atomization of water-based paint, which was previously difficult to do with the KIWAMI-1 side cup, using the dedicated B14 "aqua" cap. I was allowed to. By setting the basic coating conditions to a hand pressure of 0.15 MPa and a spraying distance of 150 mm, coating efficiency has been dramatically improved, and by creating a large flat pattern of 235 mm, we have significantly reduced coating unevenness.

Main unit features

・Ergonomic design with an emphasis on functionality

・Simple maintenance

・Equipped with a new air valve seat set (structure that minimizes individual differences between spray guns)

・Adopts twilight chrome plating that is easy to clean and has strong corrosion resistance

| format | Paint/liquid supply method | Nozzle diameter [mm] | Blow air pressure [MPa] | Paint/liquid spray amount [mL/min] | (1) Pattern opening/spraying distance [mm] | Air usage [L/min] | spray gun type | nozzle shape | air cap format | Cap internal pressure [MPa] | Mass [g] | Recommended paint/liquid viscosity [sec/NK-2] | Atomization state | spray pattern | Wetted parts material | Required compressor [kW] | Connection port size Air | Connection diameter Paint | Purpose | Noise value [dB] | Operating ambient temperature [℃] | Working fluid temperature [℃] | Maximum operating air pressure [MPa] | accessories | remarks | old model |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KIWAMI-1-13B10 | gravity type | 1.3 | 0.15 | 140 | 240/150 | 200 | General purpose | straight nozzle | KIWAMI-1-B10 | -- | 290 | 12 | Highly fine particles | Round to flat blowing | stainless | 0.75~1.5 | G1/4B male | G1/4B male | auto repair | 79 | 5~40 | 5~43 | 0.70 | brush | -- | W-101-1310BG |

| KIWAMI-1-16B12 | gravity type | 1.6 | 0.18 | 155 | 275/200 | 220 | General purpose | straight nozzle | KIWAMI-1-B12 | -- | 290 | 15 | Highly fine particles | Round to flat blowing | stainless | 0.75~1.5 | G1/4B male | G1/4B male | auto repair | 79 | 5~40 | 5~43 | 0.70 | brush | -- | -- |

| KIWAMI-1-18B14 | gravity type | 1.8 | 0.15 | 175 | 235/150 | 180 | General purpose | straight nozzle | KIWAMI-1-B14 | -- | 290 | 15 | Highly fine particles | Round to flat blowing | stainless | 0.75~1.5 | G1/4B male | G1/4B male | auto repair | 79 | 5~40 | 5~43 | 0.70 | brush | -- | -- |

specification

Persian

Persian  English

English