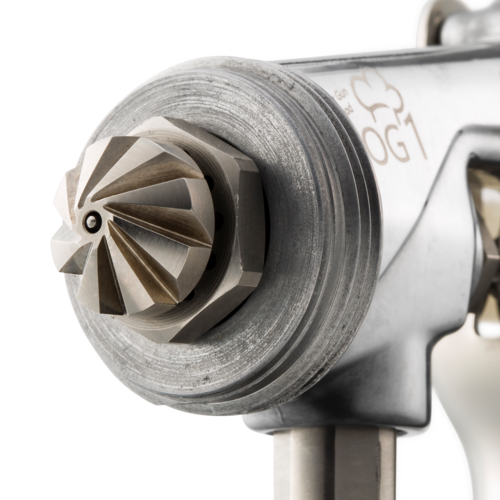

Newly designed nozzle that meets the requirements of the food liquid coating process

The newly designed swirling flow nozzle is exclusively for round blowing, and the eight slits cut into the tip of the nozzle allow the atomized air to spout out while swirling, so the atomized particles also fly while swirling.

This structure enables application with a wider round pattern than conventional spray guns even at low atomization pressure.

This not only improves work efficiency by allowing application over a large area, but also allows the material to adhere to vertical surfaces by simply applying it vertically into recesses such as bread molds.

In addition, low atomization pressure can also reduce material scattering.

In addition, as the atomization pressure is increased, straightness is added to the swirling flow, and although the pattern width becomes smaller, the straightness of the flying particles increases, making it easier for them to penetrate into the recesses.

Problems with the food solution application process

The food solution application process is not equipped with an exhaust system unlike paint factories.

When food liquids and paints are atomized by a spray gun, they scatter all over the place. If there is an exhaust system, the scattered materials will be collected and the work environment will be less contaminated, but in food manufacturing factories without exhaust systems, the materials will not only deteriorate the working environment but also cause foreign matter to be mixed in. It will become.

Therefore, in the food solution application process, it is necessary to make the pattern width as narrow as possible and use the atomization pressure as low as possible to suppress material scattering. However, if you lower the atomization pressure with a regular spray gun, the pattern width will inevitably become narrower, reducing work efficiency.

Therefore, to solve this problem, we have designed a new swirl flow nozzle!

●Applications

・For applying release oil during molding and baking processes

・Applying to bread-shaped molds and molds with recesses

●Target models

・FOG1-H18VP/-H18VG (wide-angle round blown)

・FOG1-H18VGC (wide-angle round blown main body/container)

specification

| format | spray gun type | Nozzle diameter [mm] | nozzle shape | Blow air pressure [MPa] | Air usage [L/min] | Paint ejection amount [mL/min] | Mass [g] | Connection port size Air | Connection port size Food liquid | old model | remarks |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FOG1-H18VP | gravity type | 1.8 | straight | 0.20 | 210 | 300 | 295 | G1/4B male | G1/4B male | -- | -- |

| FOG1-H18VG | gravity type | 1.8 | straight | 0.20 | 210 | 370 | 295 | G1/4B male | G1/4B male | -- | -- |

Persian

Persian  English

English