Equipped with afterpurge function and other safety mechanisms as standard

After burner operation is complete, the afterpurge function works to cool down the inside of the furnace.

After cooling is complete, the circulation fan will automatically stop.

Equipped with an earthquake detector, gas pressure switch, wind pressure switch, and ignition confirmation relay as standard equipment.

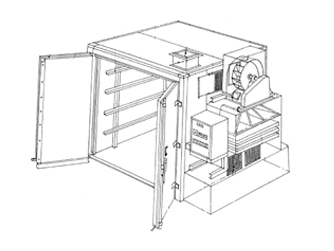

The ceiling panel has an explosion-proof opening in the front.

Easy to operate

Drying temperature and drying time settings, burner operation, circulation fan operation, etc. can be centrally controlled from the control panel.

Error indications are coded and displayed on the control panel.

For the 2-burner type, the control panel can be connected to a parent and child using one communication line, and can be operated with one unit on each side. Independent operation of the parent unit and slave unit can be switched with a switch.

Stable furnace temperature

A hot air circulation method is adopted, and time proportional control is performed by a microcomputer. Furthermore, the air outlet inside the furnace is equipped with a gallery for adjusting the wind direction as standard to ensure uniform temperature within the furnace (within ±10℃).

The CUG type uses a special gun-type burner that has excellent ignitability and is easy to maintain.

The CUE type uses a finned sheathed heater with good thermal efficiency.

Economical with low fuel consumption & heats up in a short time

Since it is an electric type, it is easier to install than a gas type.

It takes only 18 minutes to heat up to 200℃ (CUG-444B), increasing the rotational efficiency of work.

In addition, filters are installed at the fresh air intake and the outlet inside the furnace to prevent dust from adhering.

The inner and outer plates are molten aluminum-zinc alloy plated steel sheets. Since it is not painted, there is no generation of dust and

it can be shut out.

The interior of the furnace is spacious, space-saving, and easy to divide.

The internal dimensions of the furnace are converted into a meter module, increasing the internal volume by 23 to 25% for the CUG type and 21 to 25% for the CUE type compared to conventional models.

A slim type that integrates a hot air generation chamber and an operation panel.

With recycling in mind, it is easy to disassemble.

It is also easy to replace only the insulation material (glass wool).

specification

| format | Furnace body external dimensions [mm] (W×H×L) | Effective dimensions [mm](W×H×L) | Furnace interview [㎥] | Heater capacity [kW] | Number of shelf supports | door | Mass [kg] | Total electrical capacity [kW] | Primary side wiring [㎟] |

|---|---|---|---|---|---|---|---|---|---|

| CUE-332C | 1,700×1,580×1,160 | 1,300×1,390×980 | 2.3 | 6×3 | Four | 2-panel double door | 860 | 18.4 | -- |

| CUE-343C | 1,700×2,080×1,660 | 1,300×1,890×1,480 | 4.5 | 8×3 | Five | 2-panel double door | 1,220 | 24.8 | 30 |

| CUE-444C | 2,200×2,080×2,160 | 1,800×1,890×1,980 | 8.0 | 10×3 | Five | 2-panel double door | 1,660 | 30.8 | 38 |

Persian

Persian  English

English