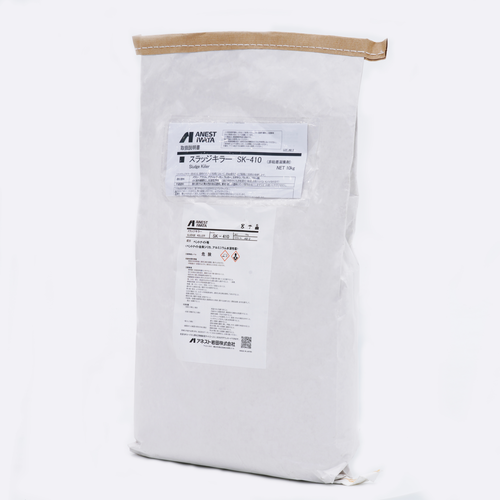

Powder booth treatment agent

Dosing method (SK-410)

[Initial dosing]

This is the amount to put in for the first time when using it for the first time or changing the water.

Situation Water condition Input amount When

a new pH adjustment booth is installed or

when the water is replaced Clean water 0.03% of the water volume

(0.3 kg per 1 ton of water) Unnecessary*2

When the treatment agent is changed When the

previous treatment agent with sludge remains 0.1% to 0.3% of the amount of water *1

(per 1 ton of water → 1kg to 3kg)

*1 Add gradually while checking the condition of the sludge and foaming status. In the case of water-soluble paints,

adding a large amount (approximately 1 kg) at once will cause a coagulation effect.

At this time, a large amount of sludge is formed due to the strong coagulation effect, so care must be taken to prevent clogging of the filter mesh.

*2 Basically, pH adjustment is not required.

However, if the pH of the booth water is below 7 due to the effects of the paint you are using or the previous treatment agent, in order to prevent booth corrosion, gradually

add a commercially available caustic soda aqueous solution (pH adjuster), being careful not to cause foaming, to adjust the pH. Please adjust.

[Daily input]

Contents to be managed on a daily basis. Fill in the basic information, but please adjust while checking the sludge condition.

① Divide the sludge into portions for effective non-sticking [morning and lunch]

② Add a large amount at the end of the work [evening] for easy sludge collection.

specification

| format | packing | Collection booth refresher | Collection Manual collection | Applicable paint Lacquer/phthalic acid | Applicable paint melamine/amino alkyd | Applicable paint polyester | Applicable paint acrylic | Applicable paint polyurethane | Applicable paint 2-component clear paint | UV | water soluble paint | SDS serial number |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SK-410-10 | 10kg (powder) | 〇 | △ | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | △ | AC013-03 |

Persian

Persian  English

English