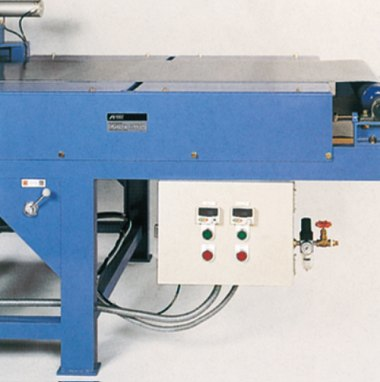

Features

・This is an economical, resource-saving coating machine that does not waste paint.

・Provides a uniform finish and a beautiful painted surface.

・Speed painting is possible with a conveyor speed of 40 to 120 m/min.

- No paint mist, providing a sanitary working environment.

・The double head type can also be painted with two-component paint.

-Easy to handle, no special painting techniques required.

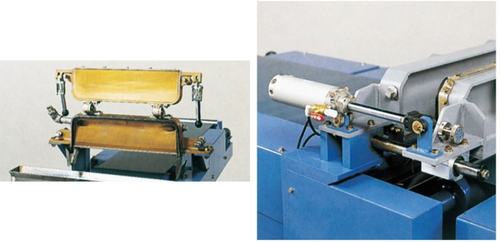

Principle of flow coater

Principle of Flow Coater

A thin curtain-like (film-like) film of constant width is made to constantly flow down from above, and a conveyor passes underneath it to coat the object.

All paint that does not stick to the object to be painted is collected and circulated by a pump, so there is no wastage of paint.

Range of liquid used

●Various paints●Adhesives●Strip agents●Photosensitizers●Printing processing liquids/dyes●Others

It is used in these places.

- Fusuma materials - Furniture - Buddhist altars

, shelves, table tennis tables, flooring

, decorative panels, exterior wall materials, various building materials

, steel plates, mirrors, leather, skis,

measuring tape, car rearview mirrors, printed circuit boards, gaskets

, tire air tubes, waterproofing Sheet/vibration-proof rubber

specification

| format | [Head] Head model | [Head] Curtain full width [mm] | [Head] Effective application width [mm] | [Head] Material | [Head] Opening/closing method | [Head] Vertical distance adjustment | [Edge] Adjustment range [mm] | [Edge] Material | [Pump] Drive motor [kW] | [Pump] Rotation speed display | [Pump] Motor structure | [Pump] Motor conduction method | [Pump] Discharge amount (fresh water) [L/min] | [Pump] Paint container [L] | [Pump] Structure | [Pump] Paint filter chamber [♯] | [Pump] Paint bypass circuit | [Pump] Paint hose [Φmm] | [Conveyor] Drive motor | [Conveyor] Speed display | [Conveyor] Speed range [m/min] | [Conveyor] Motor structure | [Conveyor] Endless belt [mm] | [Conveyor] Bearing spacing [mm] | [Conveyor] Tension | Electrical control panel | Wiring material | Paint color Aircraft | Paint color control panel | Other body dimensions [mm] | Others Conveyor height [mm] | Mass [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FL-S3G | single head | 450 | 300 | Bronze casting (gun metal) | top and bottom hinge | 100,150,200 | 0~1.0 | SUS | 0.75/4 pole | Hz numerical display by inverter | Increased safety explosion-proof type | Motor direct connection | twenty five | Ten | centrifugal style | #30, #40, 1 each | Nothing | 19×650/soft vinyl | 0.75/4 pole | Hz direct reading display by inverter | 40~120 | Totally enclosed external fan type | Width 300mm, polyurethane | 180 | Take-up type | -- | Captire code: Prica wiring | -- | -- | -- | -- | -- |

| FL-S6G | single head | 720 | 600 | Fluorine coating on steel | Horizontal drive using air cylinder | 100,150,200 | 0-1.0 | SUS | 0.75/2 poles | Hz numerical display by inverter | Increased safety explosion-proof type | Motor direct connection | 85 | 20 | centrifugal style | #30・#40 | Yes | φ25×1400mm, PVC acetate | 0.75KW/4 poles | Hz direct reading display by inverter | 40~120m/min | Totally enclosed external fan type | Width 600mm, polyurethane | 230 | Take-up type | Pump, conveyor: push button ON/OFF | Cabtire cord, Prika wiring | -- | -- | -- | -- | 620 |

| FL-S12G | single head | 1320 | 1200 | Fluorine coating on steel | Horizontal drive using air cylinder | 100,150,200 | 0-1.0 | SUS | 0.75/2 poles | Hz numerical display by inverter | Increased safety explosion-proof type | Motor direct type | 85 | 40 | centrifugal style | ♯30・♯40, 1 piece each | Yes | φ25×1400mm, PVC acetate | 1.5kW/4 poles | Hz direct reading display by inverter | 40~120m/min | Totally enclosed external fan type | Width 1200mm, polyurethane | 230 | Take-up type | Pump, conveyor: push button ON/OFF | Cabtire cord, Prika wiring | -- | -- | -- | -- | 920 |

Persian

Persian  English

English