Purpose

Can be used for rotating coating of small resin and metal objects.

Features

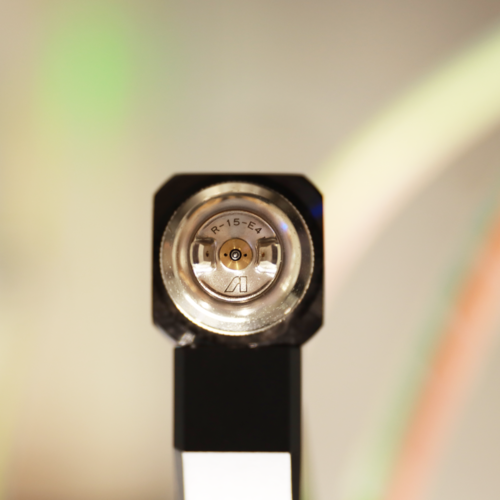

We have achieved the "short distance painting and low air volume" necessary for more efficient rotary painting. Forms a flat and wide pattern even at short distances and with a small amount of air.

・Remote adjustment of pattern width

Since the center air and corner air are each controlled independently, the pattern width can be changed remotely during painting, making it easier to prevent overspray.

- Compact body

allows installation in a small space, and can be used with painting robots and automatic painting machines.

What is a manifold?

This spray gun has an independent structure where the automatic spray gun body and the part (manifold) fixed to the stay are independent.

・You can maintain the automatic gun body without removing the air and paint tubes.

・In the event that a problem occurs with the cap nozzle during painting, only the automatic gun body can be quickly replaced.

- In the case of rotational painting, it is possible to easily return to the origin without changing the setting of the fixed stay.

High-performance type automatic spray gun

This is an automatic spray gun that can independently control atomization air and pattern air (no built-in air valve). Therefore, by remotely changing the pattern opening when performing follow-up painting with a robot, overspray can be reduced and paint can be saved.

specification

| format | Paint/liquid supply method | Nozzle diameter [mm] | Blow air pressure Atomizing air [MPa] | Paint/liquid spray amount [mL/min] | (1) Pattern opening/spraying distance [mm] | Air usage [L/min] | spray gun type | nozzle shape | air cap format | Mass [g] | Recommended paint/liquid viscosity [sec/NK-2] | Blow air pressure Pattern air [MPa] | Atomization state | spray pattern | Wetted parts material | Body material | Required compressor [kW] | Connection port size Atomizing air | Connection size pattern air | Connection port size Operating air | Port size Paint/liquid | Purpose | Noise value [dB] | Operating ambient temperature [℃] | Working fluid temperature [℃] | Maximum operating air pressure [MPa] | accessories | remarks |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WRA-M50-102P | Pressure feeding type | 1.0 | 0.12 | 50 | 115/100 | 78 | General purpose | straight nozzle | WRA-M50-E2 | 270 | Ten | 0.12 | Highly fine particles | Round to flat blowing | aluminum, stainless steel | Aluminum | 1.5~2.2 | Φ8 tube | Φ8 tube | Φ6 tube | Φ6 tube | -- | 63.6 | 5~40 | 5~43 | 0.68 | -- | -- |

| WRA-M50-S1 | Pressure feeding type | 1.0 | 0.15 | 100 | 125/100 | 77 | General purpose | straight nozzle | WRA-M50-E4 | 160 | Ten | 0.12 | Highly fine particles | Round to flat blowing | aluminum, stainless steel | Aluminum | 1.5~2.2 | Rc1/8 female | Rc1/8 female | Rc1/8 female | Rc1/8 female | -- | 63.6 | 5~40 | 5~43 | 0.68 | -- | For painting robot (SWAN) only |

English

English  Persian

Persian