What is a mold release agent spray gun?

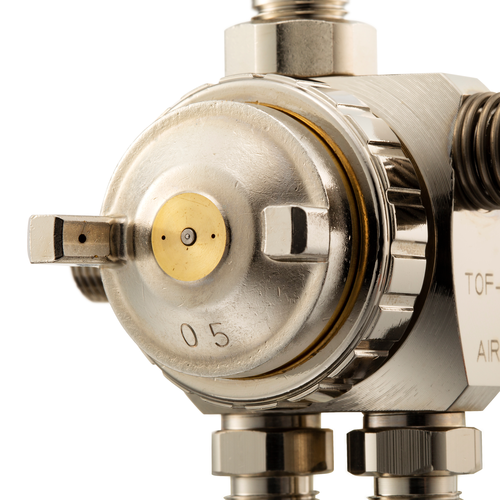

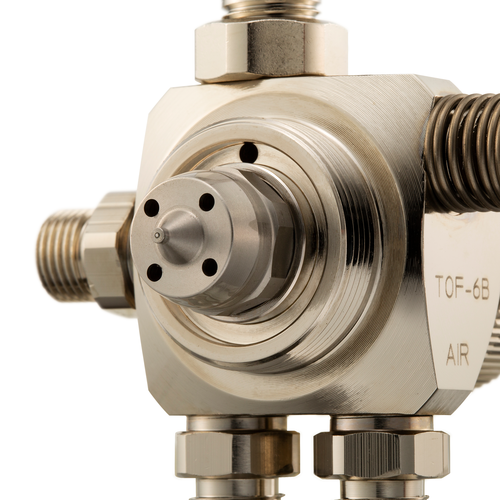

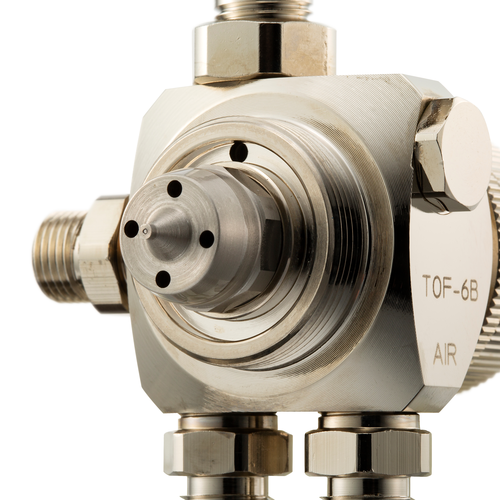

This is a spray gun and equipment dedicated to mold release agents for manufacturing rubber molding, resin molding, die casting, casting products, etc. We offer a wide range of wide pattern hand spray guns. By using a special spray gun for mold release agent, the molded product can be easily removed from the mold through proper atomization, helping to prevent damage to both the molded product and the mold.

specification

| format | Paint/liquid supply method | Nozzle diameter [mm] | Blow air pressure Atomizing air [MPa] | Paint/liquid spray amount [mL/min] | (1) Pattern opening/spraying distance [mm] | Air usage [L/min] | spray gun type | nozzle shape | air cap format | Mass [g] | Recommended paint/liquid viscosity [sec/NK-2] | Atomization state | spray pattern | Wetted parts material | Body material | Required compressor [kW] | Connection port size Atomizing air | Connection size pattern air | Connection port size Operating air | Port size Paint/liquid | Purpose | Noise value [dB] | Operating ambient temperature [℃] | Working fluid temperature [℃] | Maximum operating air pressure [MPa] | accessories | remarks |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TOF-6B-05 | Suction type, gravity type, pressure feeding type | 0.5 | 0.30 | 60 | 200/300 | 60 | General purpose | straight nozzle | 05 | 330 | -- | General-purpose fine particles | Round to flat blowing | brass, stainless steel | Brass | 0.75~1.5 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

| TOF-6B-10 | Suction type, gravity type, pressure feeding type | 1.0 | 0.30 | 250 | 250/300 | 80 | General purpose | straight nozzle | Ten | 330 | -- | General-purpose fine particles | Round to flat blowing | brass, stainless steel | Brass | 0.75~1.5 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

| TOF-6B-13 | Suction type, gravity type, pressure feeding type | 1.3 | 0.30 | 360 | 350/300 | 100 | General purpose | straight nozzle | 13 | 330 | -- | General-purpose fine particles | Round to flat blowing | brass, stainless steel | Brass | 1.5~2.2 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

| TOF-6B-20 | Suction type, gravity type, pressure feeding type | 2.0 | 0.30 | 600 | 400/300 | 140 | General purpose | straight nozzle | 20 | 330 | -- | General-purpose fine particles | Round to flat blowing | brass, stainless steel | Brass | 1.5~2.2 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

| TOF-6RB-05 | Suction type, gravity type, pressure feeding type | 0.5 | 0.30 | 60 | 50/300 | 40 | General purpose | straight nozzle | 0.5 | 310 | -- | General-purpose fine particles | For round blowing only | brass, stainless steel | Brass | 0.75~1.5 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

| TOF-6RB-10 | Suction type, gravity type, pressure feeding type | 1.0 | 0.30 | 250 | 70/300 | 50 | General purpose | straight nozzle | Ten | 310 | -- | General-purpose fine particles | For round blowing only | brass, stainless steel | Brass | 0.75~1.5 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

| TOF-6RB-13 | Suction type, gravity type, pressure feeding type | 1.3 | 0.30 | 360 | 80/300 | 55 | General purpose | straight nozzle | 13 | 310 | -- | General-purpose fine particles | For round blowing only | brass, stainless steel | Brass | 1.5~2.2 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

| TOF-6RB-20 | Suction type, gravity type, pressure feeding type | 2.0 | 0.30 | 600 | 90/300 | 85 | General purpose | straight nozzle | 20 | 310 | -- | General-purpose fine particles | For round blowing only | brass, stainless steel | Brass | 1.5~2.2 | G1/8 male | -- | G1/8 male | G1/8 male | For applying mold release agent | 69.4 | 5~40 | 5~43 | 0.68 | operating instructions | -- |

English

English  Persian

Persian